Vee Bee protects flow processes and operations against contaminates with reliable and cost-effective strainer and filtration equipment.

Strainers and filtration components for industrial processes are vital for protection against asset damage and operational downtime. Contaminates can enter the process line and cause millions in financial damage.

Vee Bee specialises in the design and manufacture of strainer, filtration and pressure vessel equipment designed to protect against and manage contaminants that might enter the process or flow system.

Typical applications protected by using Vee Bee

Media applications: lubricants, chemicals, fuels and gases, steam and water.

Equipment applications: Boilers, condensers, flowmeters, heat exchangers, nozzles, oil burners, pumps, valves and regulators.

Sector applications: LNG, water treatment, pulp and paper, steel mills, petrochemical, automotive, pharmaceutical, nuclear, power generation, utilities, chemical, marine, process, paint, food and beverage, adhesives, mining, HVAC, shipbuilding and inks.

Geographical: Worldwide coverage.

Typical range of process protection solutions from Vee Bee

Equipment is designed to the exacting specification and application of the project so a definitive list is not possible.

A broad definition of product categories can be provided as an example of Vee Bee capabilities; these include: asket strainers, conical strainers, cartridge filters, dual type strainers, mono type strainers, tee type strainers and y type strainers; along with accessories, spares and a build to print service.

Dependable strainer and filtration solutions

Quality control in all aspects of the design and production process confirms how seriously Vee Bee takes its responsibility in maintaining its reputation for delivering reliable, robust and cost-efficient filtration solutions.

Vee Bee analysis and design resources

Vee Bee design capabilities are unmatched in the industry and include flow and application analysis along with metallurgical and construction assessments. This process applies to everything from strainer pattern to casing design and manufacture – all from the exacting perspective of the particular application.

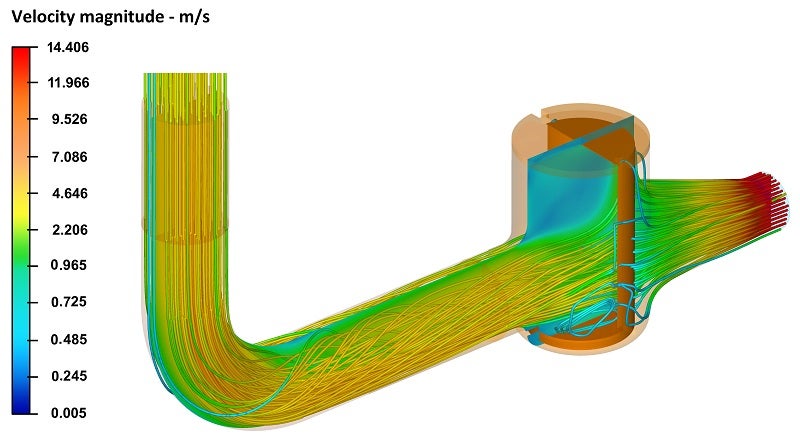

Vee Bee has exceptional and experienced engineers that work on rigorous material and component supply chain processes, 3D modelling, CFD and heat transfer dynamics that allow the modelling of heat, mass, phase change, chemical reaction and stress variables along with related solid structure deformation predictions and countering design solutions.

System and operational analysis include velocity and pressure distribution along with upstream piping effect and flow dynamics.

Proof testing is also part of the process.

Approvals

Vee Bee Strainers and Filtration equipment is used by many major operators around the world and has been confirmed over the last six decades to be the most cost-effective solution in protecting operations against contaminants.

Accreditations

- The following is an example of the accreditations available from Vee Bee

- Welders Coded to ASME IX and BS EN 287

- NDT personnel qualified to ASNT Level II for DPI & MPI

- Additional NDT to ASNT II / PCN Level II for Radiography, MPI, DPI & UT

- NDT can be offered to any Internationally recognised standard

- Paint Inspection can be carried using subcontracted operators to NACE Level II

- Strainer & Filter Qualifications to any recognised regulations, dependant on client requirements: example include Russian, Chinese, Canadian, Algerian registrations

Due diligence when commissioning filtration equipment

Vee Bee is unmatched in the world for confirming the following due diligence requirements: Material Certificates, Traceability Audit, Quality Certification, Insurance Certificates and Experience List.

A Vee Bee Due Diligence Confirmation Pack that includes a comprehensive Approvals and Experience List if available during the specification brief process.

Vee Bee strainer and filtration solutions

Protecting your assets and operations is too important to leave to anyone else.