Veotec is a specialist manufacturer of air intake systems. Its range of products includes diesel and gas turbine engines and HVAC systems, which have been designed to deal with the effects of ingress of water, salt, mist, dust and sand in adverse conditions.

The company offers a broad range of products, from weather louvres to trace-heated moisture eliminators and filter housings.

Veotec’s clients and end users include offshore oil rigs and shipyards.

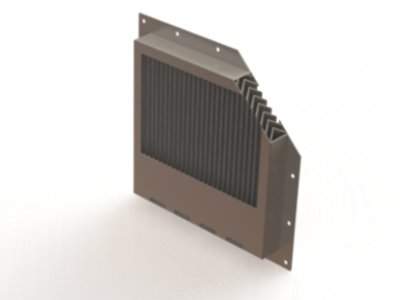

Weather louvres

A robust construction from galvanised steel, marine-grade aluminium or stainless-steel, the weather louvre (WL) is a basic weather protection device for removing corrosive rain water and mist. Veotec can additionally design closing mechanisms to create a weather-tight hatch for extreme conditions.

Single-stage moisture eliminators

The Veotec SE1 is a single-stage separator that removes sea spray, rain, excess water, salt and aerosol debris from air intake. It is typically used to protect HVAC equipment, ventilation systems and diesel engine air intakes.

The SE1 operates at a low-pressure loss and removes more than 90% of five-micron water particles. Built with marine-grade aluminium or high-grade stainless-steel and can be fitted with various water drainage systems.

Vanes are also available in PVC plastic.

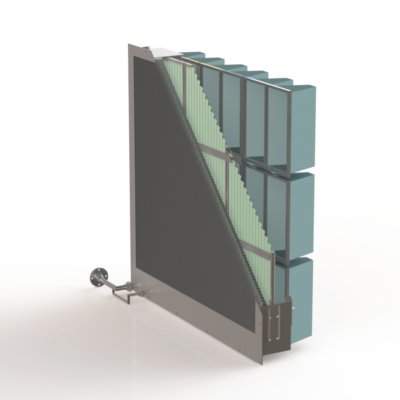

Two-stage air intake separators

The Veotec SE2 is a two-stage filter system comprising the SE1 inertial vane and filter coalescer, which operates at more than 90% removal of three-micron water particles.

The SE2 can be used as part of a gas turbine filter system and protects HVAC equipment, ventilation systems and diesel engines.

Three-stage air intake separators

The Veotec SE3 combines all the benefits of a SE2 with a third stage, additional vane separator, which allows for higher velocities up to 6m/s.

This maintains the high level of salt and moisture removal required for air intakes in offshore and coastal environments. At 4m/s, the SE3 has been tested and certified to meet IPX6 classification.

Combined, multiple-stage moisture eliminators and dust removers

The Veotec SE2F is implemented when not only moisture elimination of the highest level is required but also a high level of dust removal.

The SE2 model is combined with bag-type filters to achieve efficiencies to client specifications, but typically F7 – F9 for HVAC intakes and up to H10 – H12 for gas turbine intakes.

Trace-heated moisture eliminators

Veotec’s SETH heated inlet vanes provide protection with turbine installations operating in some of the world’s harshest environments. The heated vanes prevent inlet icing for power generation, oil and gas, HVAC equipment, ventilation systems and diesel engines.

This equipment is compatible with the Veotec WL1, SE1, SE2 and SE3 moisture eliminators.